PRODUCTS

Composite biaxial Geogrid

Category:

Composite PP Biaxial Geogrid with Nonwoven geotextile

Get expert sales advice within 12 hours.

Chat with us now for a quick response.

keywords :

Composite PP Biaxial Geogrid with Nonwoven geotextile

Product Introduction

Composite biaxial Geogrid is traditional polypropylene extruded true biaxial geogrid thermally bonded with a needle punched nonwoven geotextile

Description of Composite biaxial Geogrid

Composite biaxial Geogrid is a composite made of bi-axial polypropylene (PP) geogrid, heat bonded to a long fiber non-woven polyester geotextile that acts as a filter and soil separator. This geogrid is manufactured using a punching and drawing process whereby the polypropylene sheet is stretched in two directions, machine (longitudinal) and cross-machine (transverse). The result is a monolithic and isotropic geogrid with thick and wide ribs, thick integral nodes, and uniform square apertures. Engineered to be mechanically and chemically stable in aggressive soil environments, THIS-GEOCOMPOSITE allows sub-base drainage to help maintain structural stability, and is very effective in keeping expensive imported material from being contaminated by migration of fines from the saturated base soils. Biaxial geogrid pp composite nonwoven geotextile Biaxial geogrid pp composite nonwoven geotextile

Specification of Composite biaxial Geogrid

| BI-AXIAL GEOGRID | MD | XD | ||

| Carbon Black Content | ASTM D 4218 | % | 2.0 | |

| Ultimate Tensile Strength{1} | ASTM D 6637 | lbs/ft(kN/m) | 1645(24.0) | 1645(24.0) |

| Tensile Strength at 2% strain{1} | ASTM D 6637 | lbs/ft(kN/m) | 720(10.5) | 720(10.5) |

| Tensile Strength at 5% strain{1} | ASTM D 6637 | lbs/ft(kN/m) | 1343(19.6) | 1343(19.6) |

| Junction Efficiency{2}{3} | GRI-GC2 | % | >95 | >95 |

| Flexural Rigidity{1} | ASTM D 7748 | mg-cm | 1000000 | |

| Aperture Stability{2}{4} | US.COE | m-N/deg | 0.65 | |

| Minimum Rib Thickness | Callipered | inch(mm) | 0.07(1.7) | 0.05(1.3) |

| Aperture Size{2}{5} | Nominal | inch(mm) | 1.33(34.0) | 1.22(31.0) |

| GEOTEXTILE | ||||

| Raw Material | Polyester, Continuous filament, needle punched | |||

| Ultimate Tensile Strength{1} | ASTM D 4595 | lbs/ft(kN/m) | 781(11.4) | 781(11.4) |

| Grab Strength{1} | ASTM D 4632 | lbs(kN) | 128(0.57) | |

| Trapezoidal Tear{1} | ASTM D 4533 | lbs(kN) | 56(0.25) | |

| Elongation at Ultimate{2} | ASTM D 4595 | % | 60 | 60 |

| CBR Burst Strength{1} | ASTM D 6241 | lbs(kN) | 540(2.4) | |

| Permeability | ASTM D 4491 | cm/sec | 0.41 | |

| Apparent Opening Size O9S | ASTM D 4751 | mm | 0.12 | |

| Mass Per Unit Area{2} | ASTM D 5261 | oz/yd2(g/m2) | 6.0(200) | |

| TYPICAL ROLL DIMENSIONS | ||||

| Roll Width | ft(m) | 12.79(3.9) | ||

| Roll Length{6} | ft(m) | 164.04(50.0) | ||

Application of Composite biaxial Geogrid

1.High tensile and long-term strength

2.High tear strength

3.Excellent creep resistance

4.Flexible and durable

5.Increased pull-out resistance and compound strength

6.Optimum stability of the junction of the grid

7.High chemical and biological resistance

8.UV resistance / Cost effective

9.High resistance to installation damage and ease of installation

Our Company

Feicheng Lianyi Engineering Plastic Co., Ltd has been a leader market for more than 16 years in manufacturing geosynthetics material for domestic and export markets.

The products we product are Self Adhesive Fiberglass Geogrid,Fiberglass Geogrid,Polyester Biaxial Geogrid,Polypropylene Biaxial Geogrid,Extruded Polyethylene Geogrid,PP UX GEOGRID,Welding PET Geogrid,Polyester Reinforcing Geocomposite,Biaxial Geogrid With geotextile,Fiberglass Geogrid Stitched With Geotextile,PP Biaxial Geogrid Geocomposite,PET Nonwoven Geotextile,PP Spunbond Nonwoven Fabric,perforated Geocell,hdpe geomembrane sheet,Composite Geomembrane with Nonwoven Geotextile,Three/two Dimensional HDPE Geonet,etc

Production strength

Feicheng Lianyi Engineering Plastics Co., Ltd. is a comprehensive enterprise specializing in the research, development, manufacturing, and sales of geosynthetic, plastic, and fiberglass products. Currently, the company boasts fixed assets of RMB 800 million and employs 581 staff members, 48% of whom are graduates from domestic universities. We have established long-term cooperative relationships with several research institutes, universities, and design institutes, ensuring strong technical capabilities. Our annual production capacity reaches approximately 150,000 tons.

Our products have been exported to numerous countries and regions, including South Korea, Israel, Kuwait, Thailand, Canada, Panama, and Poland etc, earning a strong reputation in the market. Our management philosophy is to provide high-quality products and excellent service to our customers. We are committed to continuous innovation and product improvement as our core development strategy. We look forward to establishing long-term cooperative relationships with you.

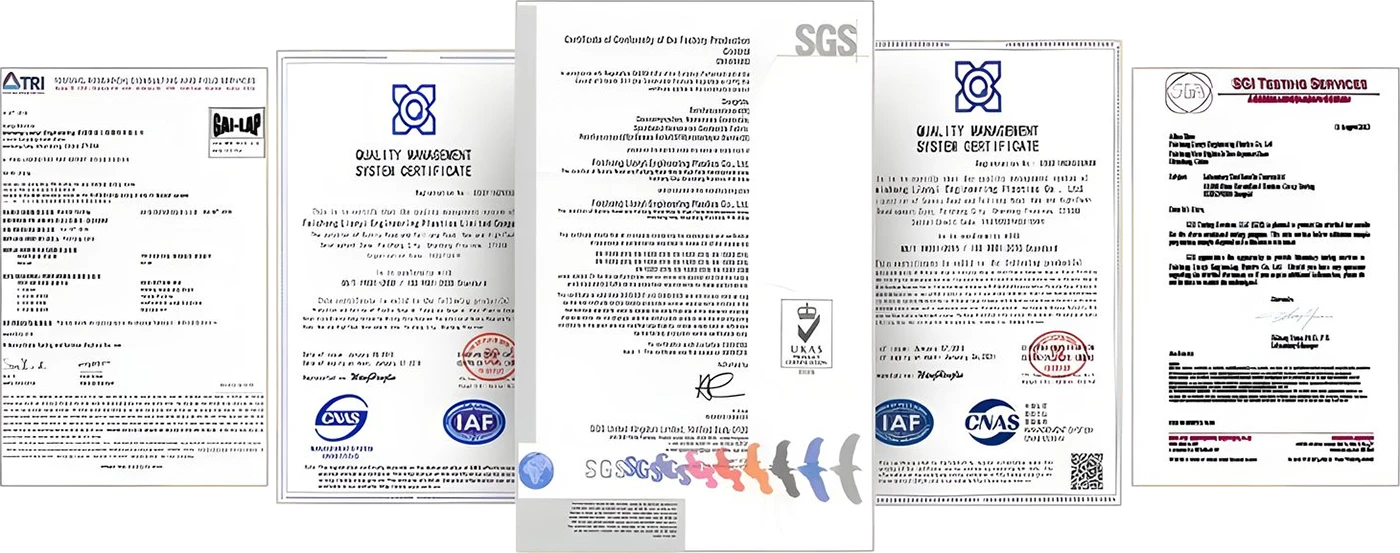

OUR CERTIFICATE

All our geosynthetic products are manufactured in adherence to the international standards for quality. We have laboratories and facilities where we test each product, allowing us to provide customers with data tests.

To ensure quality, we obtained different certifications including ISO9001, BBA, ISO 14001, and IVG. We are also certified by OHSAS 18001, RVS, ASQUAL, and Norgeospec.

Thus, ensuring that each product will be delivered with quality.

Our products are applied in these fields

Retaining Walls

Geogrids are polymer-based geosynthetic materials used to reinforce soil behind retaining walls, installed in horizontal layers that extend into the backfill. By stabilizing the soil mass, they enhance the structural integrity and load-bearing capacity of the wall system.

Soil Reinforcement

Geogrids and Geotextiles enhance soil stability by adding tensile reinforcement, improving strength and deformation resistance. These materials allow engineers to construct embankments on soft ground and design steeper earth slopes safely. Their reinforcing function provides crucial structural support where traditional soil alone would fail.

Drainage Systems

Geotextiles are used to prevent road base materials from penetrating into soft underlying soft subgrade, thus maintaining design thickness and roadway integrity. Geotextile separators also prevent fine-grained subgrade soils from being pumped into permeable, granular road bases

Erosion control

Geosynthetics provide immediate sediment stabilization while creating a supportive matrix for revegetation, with material selection based on site-specific hydraulic and topographical conditions. These engineered systems combine immediate erosion protection with long-term soil reinforcement, capable of withstanding high-velocity flows during both initial installation and subsequent vegetation establishment phases.

Filtration

Geotextiles retain soil particles while allowing water flow, utilizing a 'bridging' effect where larger particles help trap finer sediments, working best in one-directional flow. Their performance can be customized through fabric design and are often paired with drainage cores in geocomposites to prevent soil migration in drainage systems or protect riprap in waterways.

Mission

Our mission is to deliver innovative, high-quality geosynthetic solutions that empower sustainable development and enhance the resilience of infrastructure worldwide.

● Innovation: Continuously advancing our products and technologies to meet the evolving needs of the construction and environmental industries.

● Quality: Ensuring the highest standards of manufacturing to provide durable, reliable, and cost-effective geosynthetic materials.

● Sustainability: Promoting environmentally responsible practices by offering solutions that reduce environmental impact and support long-term ecological balance.

● Customer Focus: Building strong partnerships with our clients by understanding their unique challenges and delivering tailored solutions that exceed expectations.

● Global Impact: Contributing to the development of safer, more efficient, and sustainable infrastructure across the globe.

Can geotextiles be used with geogrids?

Request Information or Get a Quote

Lianyi welcomes the opportunity to work with you on your next infrastructure project. Click the link below to submit an electronic request or get contact information for our nearest location, and our team will get back to you promptly.

CONTACT US →GET A FREE QUOTE

RELATED PRODUCTS